Understanding the Sewing Manufacturing Process: From Design to Delivery

The sewing manufacturing process is a fascinating journey that takes a design concept and turns it into a finished product ready for consumers. Whether you’re new to the world of textiles or an experienced designer, understanding the steps involved in manufacturing is crucial for delivering quality products efficiently. In this article, we’ll walk you through the entire process—from initial design all the way to final delivery.

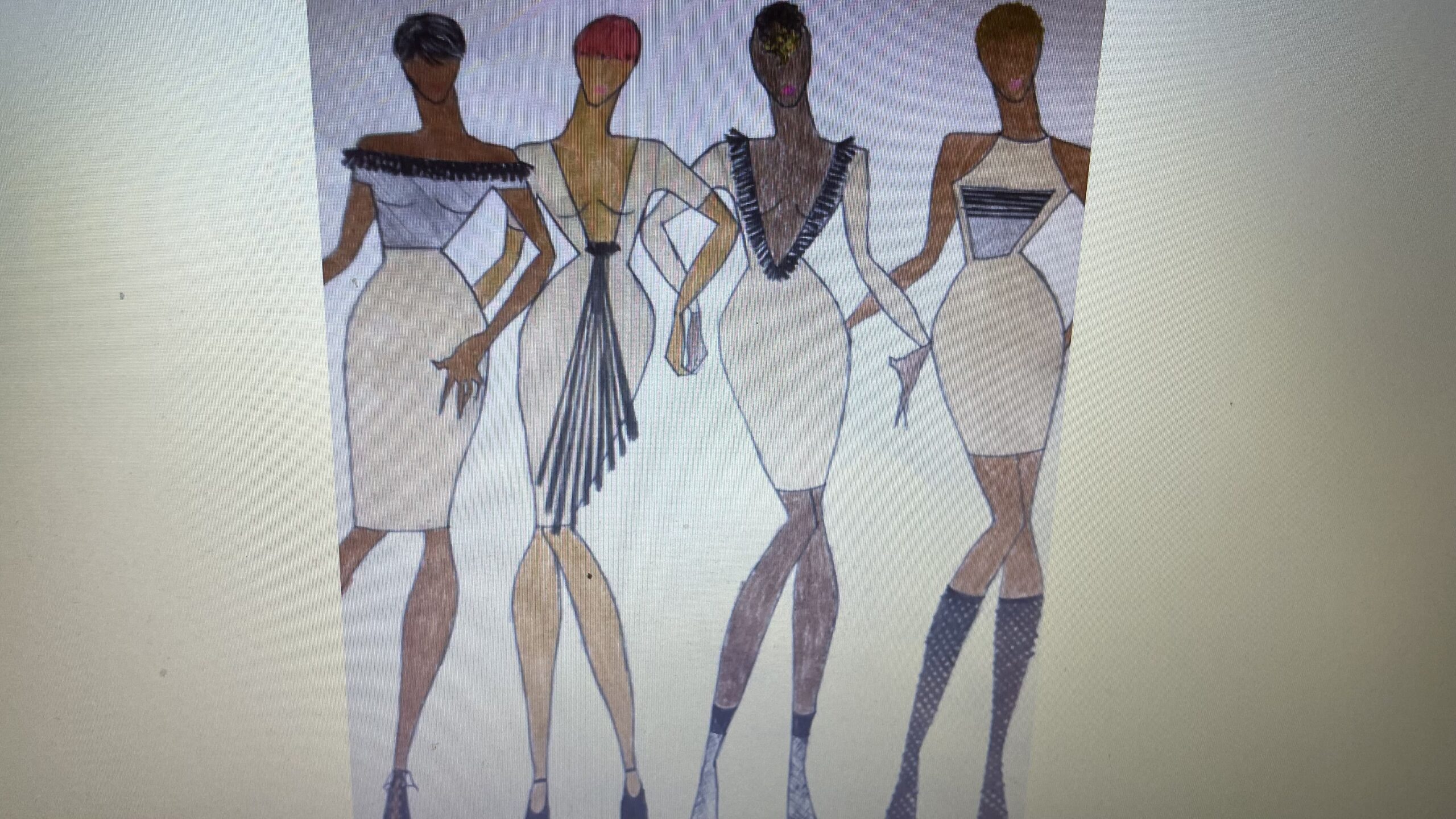

Step 1: The Design Phase

Everything begins with an idea. The design phase is where creativity takes center stage. Designers sketch their visions on paper or use digital software to create detailed illustrations of the garments or products they want to produce. This phase often involves:

- Mood boards and research: Inspiration is gathered through mood boards, fabric swatches, and market research.

- Technical sketches: Detailed drawings, often using CAD software, are created to show the technical aspects of the design.

- Prototype development: Once a design is approved, a prototype or sample is made to check fit, look, and functionality.

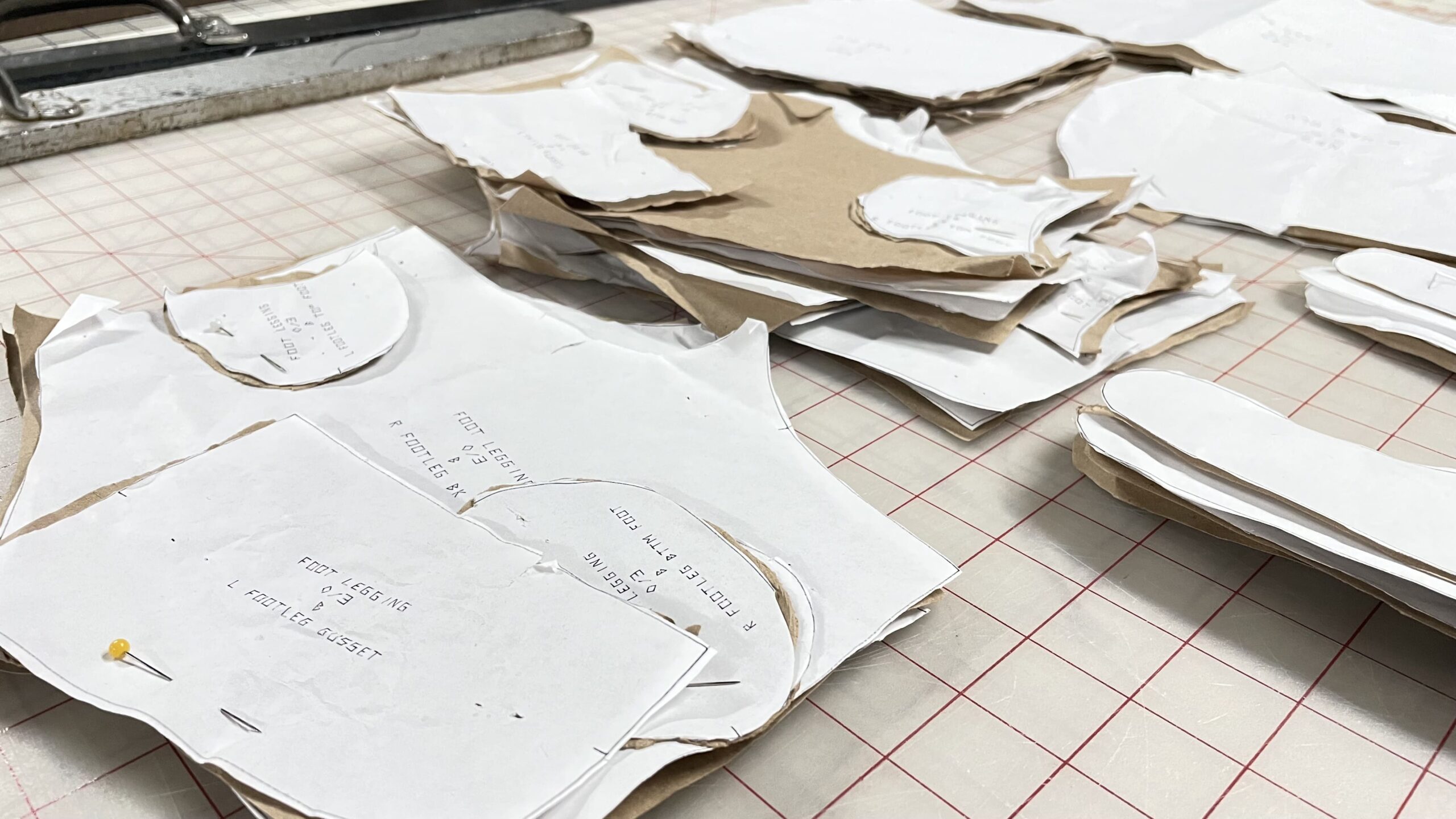

Step 2: Pattern Making & Grading

After the design is finalized, the next step is creating the pattern. A pattern is essentially a template that guides the cutting of fabric. In commercial sewing manufacturing, pattern makers will often create multiple sizes of the same design, a process called grading. Patterns can be made manually or with the help of specialized software, and accuracy at this stage is essential to ensure consistency in production.

Step 3: Fabric Cutting

With the pattern ready, the next step is cutting the fabric. In a manufacturing setting, fabric is usually cut in bulk using machines that slice through multiple layers of fabric at once. This step must be precise to avoid material waste and ensure each piece aligns perfectly for assembly. Specialized tools like laser or die cutters may be used depending on the complexity of the design.

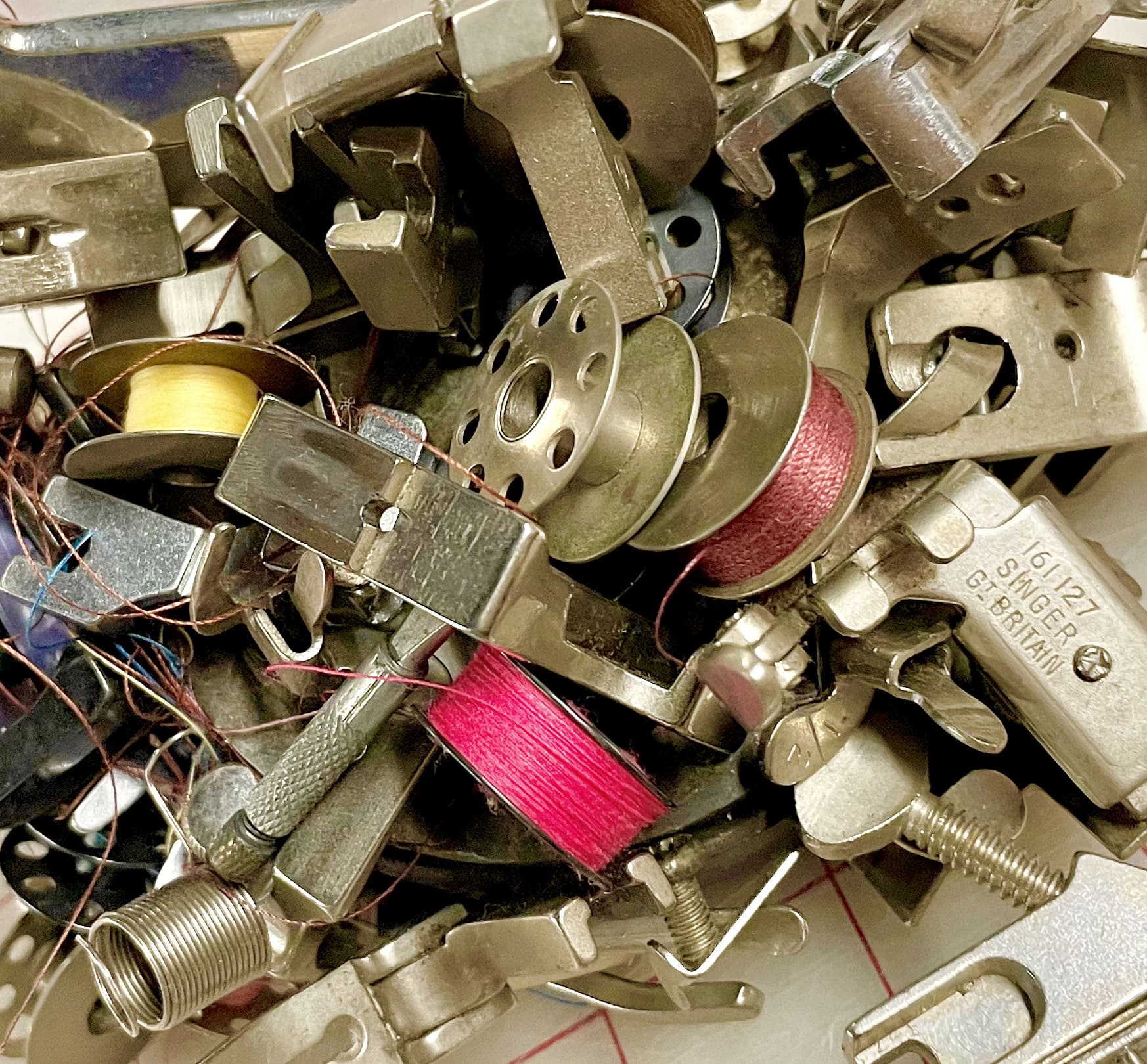

Step 4: Sewing & Assembly

Once the fabric pieces are cut, they move to the sewing department where skilled workers use industrial sewing machines to assemble the garments or products. Depending on the design, different types of stitching and construction methods may be used. This stage requires close attention to detail to ensure quality craftsmanship.

Step 5: Quality Control

Quality control is essential in sewing manufacturing to ensure that every product meets high standards. Each item is inspected for defects, such as uneven stitching, misaligned patterns, or fabric damage. If an item doesn’t meet the necessary quality standards, it is either repaired or discarded.

Step 6: Finishing & Packaging

After passing quality checks, the products go through finishing processes, such as pressing, adding labels, and final trims. Packaging is an important final step, whether the items are being sent to retailers or directly to customers. Proper packaging not only protects the product during shipping but also reflects your brand’s attention to detail.

Step 7: Delivery & Distribution

Finally, the finished products are ready for delivery. Whether shipping to retail stores or fulfilling online orders, timely and secure delivery is critical. Many manufacturers use third-party logistics providers to handle shipping and distribution, ensuring that the products reach customers efficiently.

Conclusion

Understanding the sewing manufacturing process from design to delivery is essential for anyone looking to succeed in the industry. By mastering each stage, from the creative aspects of design to the technical precision of production and quality control, you can ensure your products meet the highest standards and reach your customers on time.

Ready to Bring Your Designs to Life?

If you have a design or sewing project in mind, Sewing Patterns & more is here to help! Submit your proposals using this form, and let’s collaborate to turn your creative ideas into reality.