Here’s a possible article for your title “Sewing Manufacturing: A Beginner’s Guide”:

Sewing Manufacturing: A Beginner’s Guide

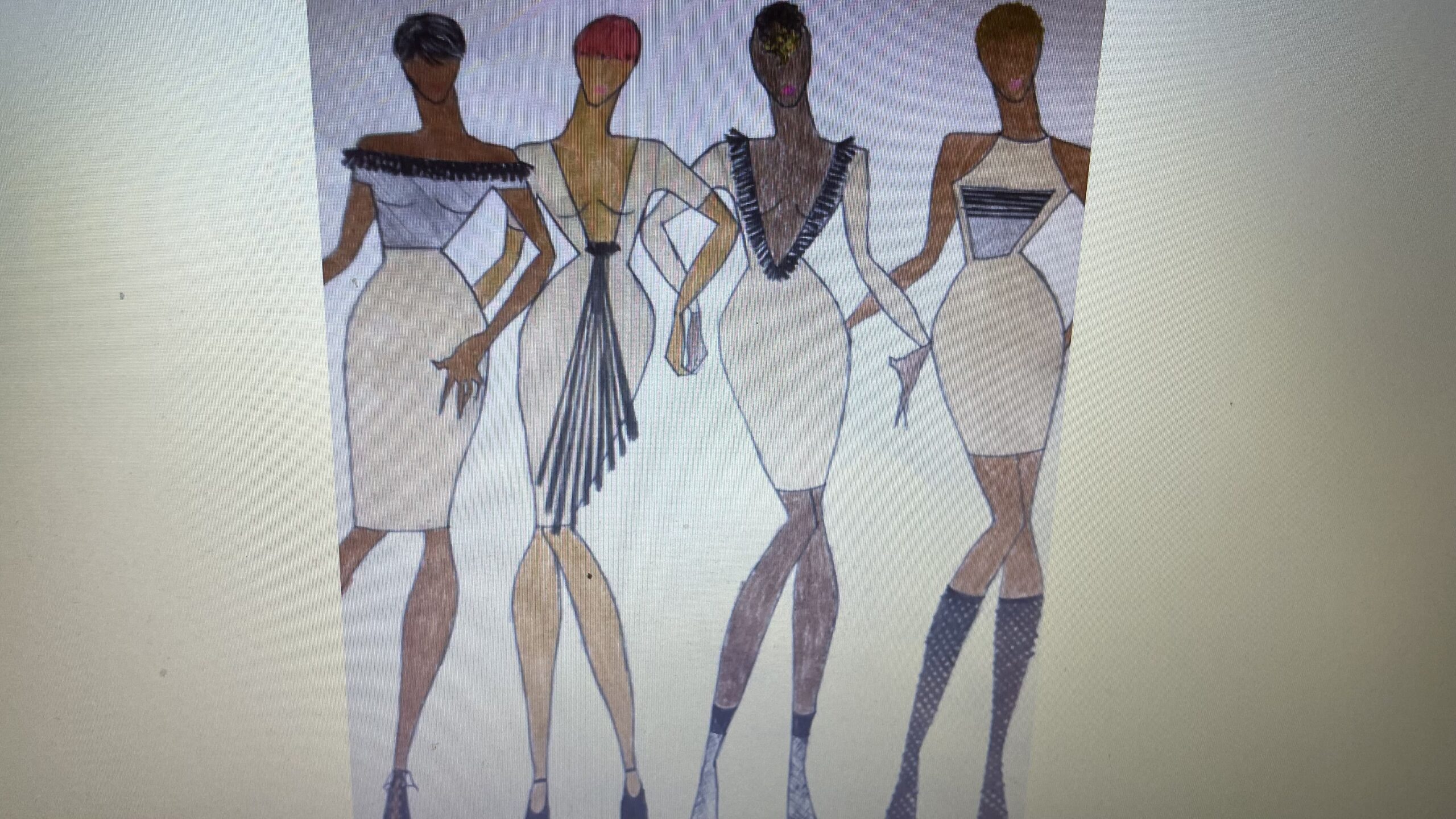

Sewing manufacturing is at the heart of the textile and fashion industry, blending creativity and technical precision to bring fabric designs to life. Whether you’re a hobbyist or someone looking to enter the business world of sewing, understanding the manufacturing process can be a game changer. In this guide, we’ll break down the essentials of sewing manufacturing and what beginners need to know to get started.

Understanding the Basics of Sewing Manufacturing

Sewing manufacturing involves the production of sewn goods at scale, using machinery and skilled labor to create garments, accessories, and various other textile products. The process generally includes:

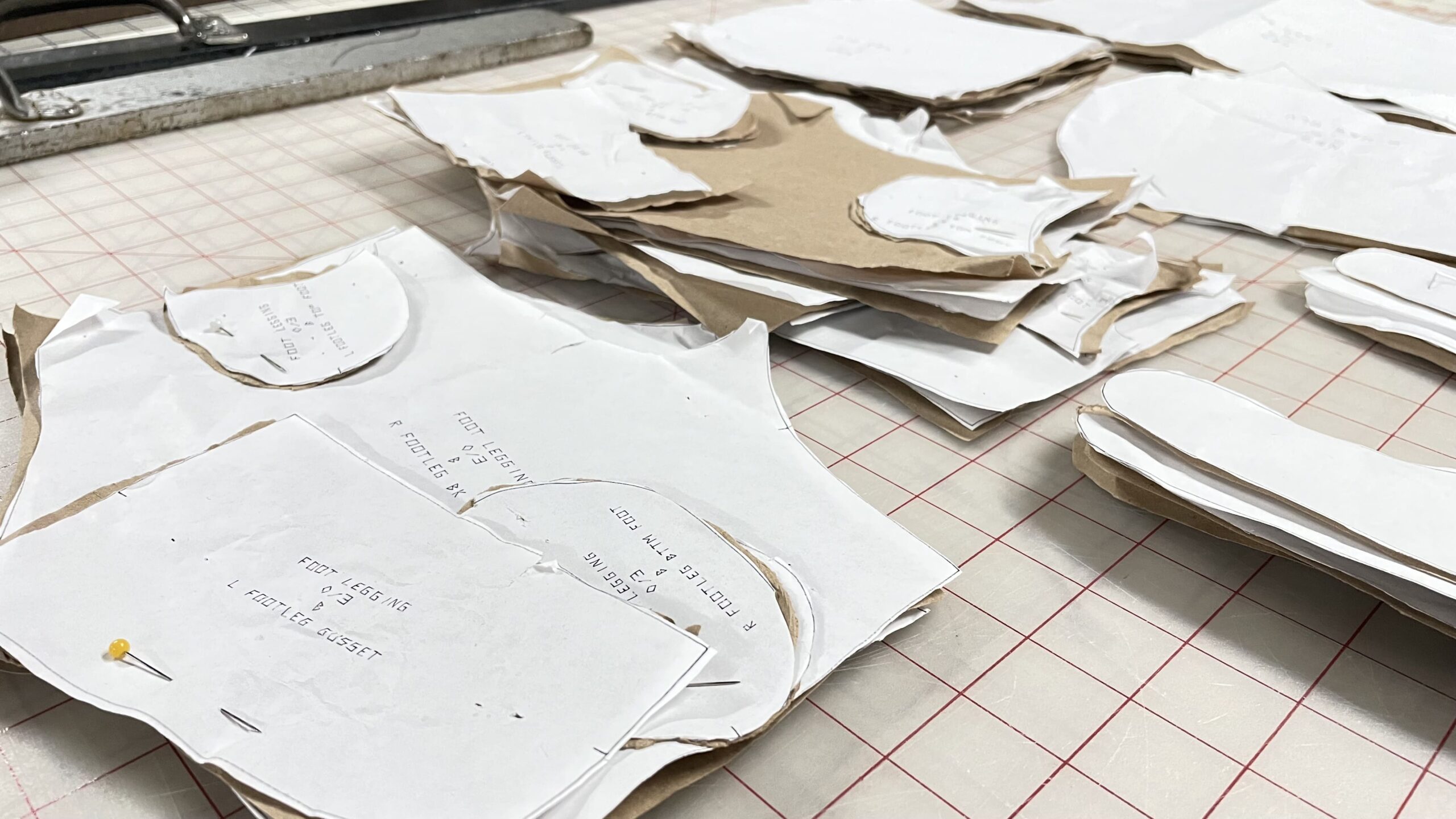

- Pattern Making: The foundation of any sewn product starts with a pattern. Pattern makers convert design sketches into templates, which guide the cutting and stitching of fabric pieces.

- Cutting: Once a pattern is created, fabric is cut to match the specifications. This is often done in bulk with specialized machines in a manufacturing environment.

- Sewing & Assembly: This is where the magic happens. Multiple sewing machines or automated systems are used to stitch the cut fabric pieces together, creating the finished product.

- Quality Control: Each item is inspected for defects, ensuring that the final product meets the desired quality standards.

- Finishing & Packaging: After passing quality checks, products may undergo additional processes like ironing, tagging, or packaging for shipping.

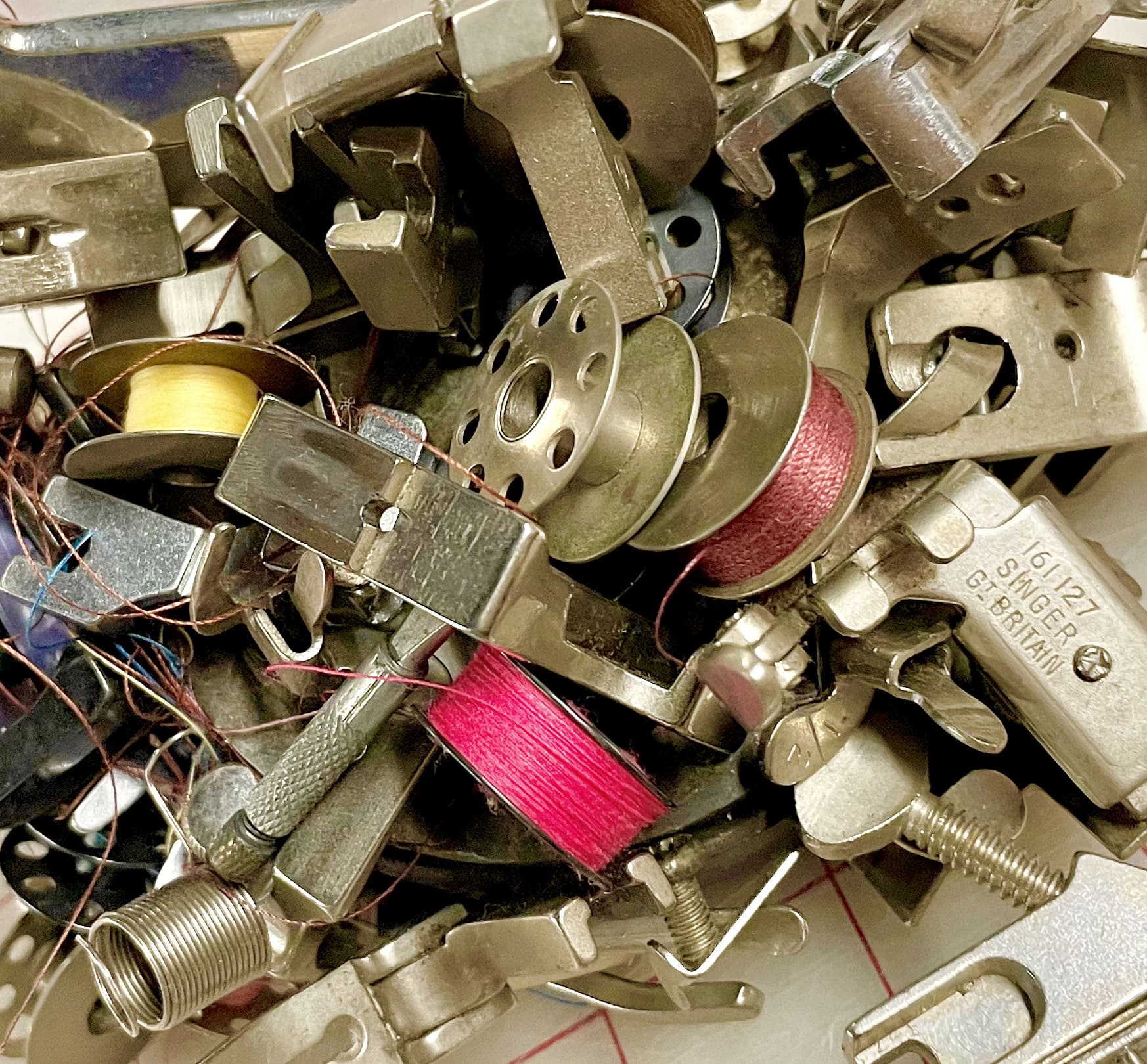

Key Equipment Used in Sewing Manufacturing

Getting started in sewing manufacturing requires some essential equipment, including:

- Industrial Sewing Machines: Unlike domestic machines, industrial models are built for speed, durability, and handling heavy fabrics.

- Cutting Machines: These are crucial for high-volume production and can vary from manual to automated options.

- Pressing & Ironing Systems: Proper finishing ensures that garments look polished and professional.

- Embroidery Machines (optional): For those looking to add decorative elements or branding to products, embroidery machines can be a great investment.

Finding Your Niche

One of the keys to success in the sewing manufacturing industry is specialization. Whether you’re focusing on fashion apparel, home décor items, or custom accessories, finding your niche will help you stand out. Research trends, analyze customer needs, and focus on perfecting a specific type of product.

How to Scale Your Sewing Manufacturing Business

Once you’ve mastered the basics and found your niche, scaling your business becomes the next step. Here are some tips for growing your sewing manufacturing company:

- Invest in Advanced Machinery: As demand increases, upgrading to more automated machines can help improve efficiency and reduce labor costs.

- Outsource Certain Processes: Consider partnering with other companies for specific services like cutting or embroidery, which allows you to focus on your core strengths.

- Optimize Workflow: Implement lean manufacturing practices to minimize waste and increase productivity.

- Market Your Brand: Use social media, online marketplaces, and trade shows to get your products in front of a larger audience.

Ready to Take the Next Step?

If you’re excited about entering the sewing manufacturing business or want to expand your current setup, we’d love to hear your ideas! Submit your proposals using this form, and let’s work together to turn your vision into reality.

Sewing Patterns & more is here to support your sewing journey every step of the way!