In sewing and textile manufacturing, quality control is crucial to ensuring customer satisfaction and building a reputable brand. At Sewing Patterns & More, we understand the importance of delivering high-quality products that meet the expectations of both designers and consumers. Whether you’re a small sewing business or part of a larger operation, implementing effective quality control can make all the difference. This article explores essential tips and strategies to help you maintain the highest standards in your sewing projects.

Why Quality Control is Essential in Sewing

For Sewing Patterns & More, quality control is not just about catching mistakes—it’s about ensuring that every product reflects the precision and care put into its creation. A poorly constructed product can harm your reputation, result in returns, and ultimately lead to lost revenue. When sewing garments, home décor, or accessories, even small issues like uneven stitches, loose threads, or misaligned patterns can affect the final look and durability of the item.

1. Use High-Quality Materials

At Sewing Patterns & More, we emphasize the importance of using high-quality fabrics, threads, and notions. Low-quality materials can weaken seams, fade after washing, or create inconsistencies during the sewing process. When you invest in durable materials from the beginning, you reduce the risk of issues arising later in production. Always test new materials for shrinkage, colorfastness, and overall durability before committing to bulk orders.

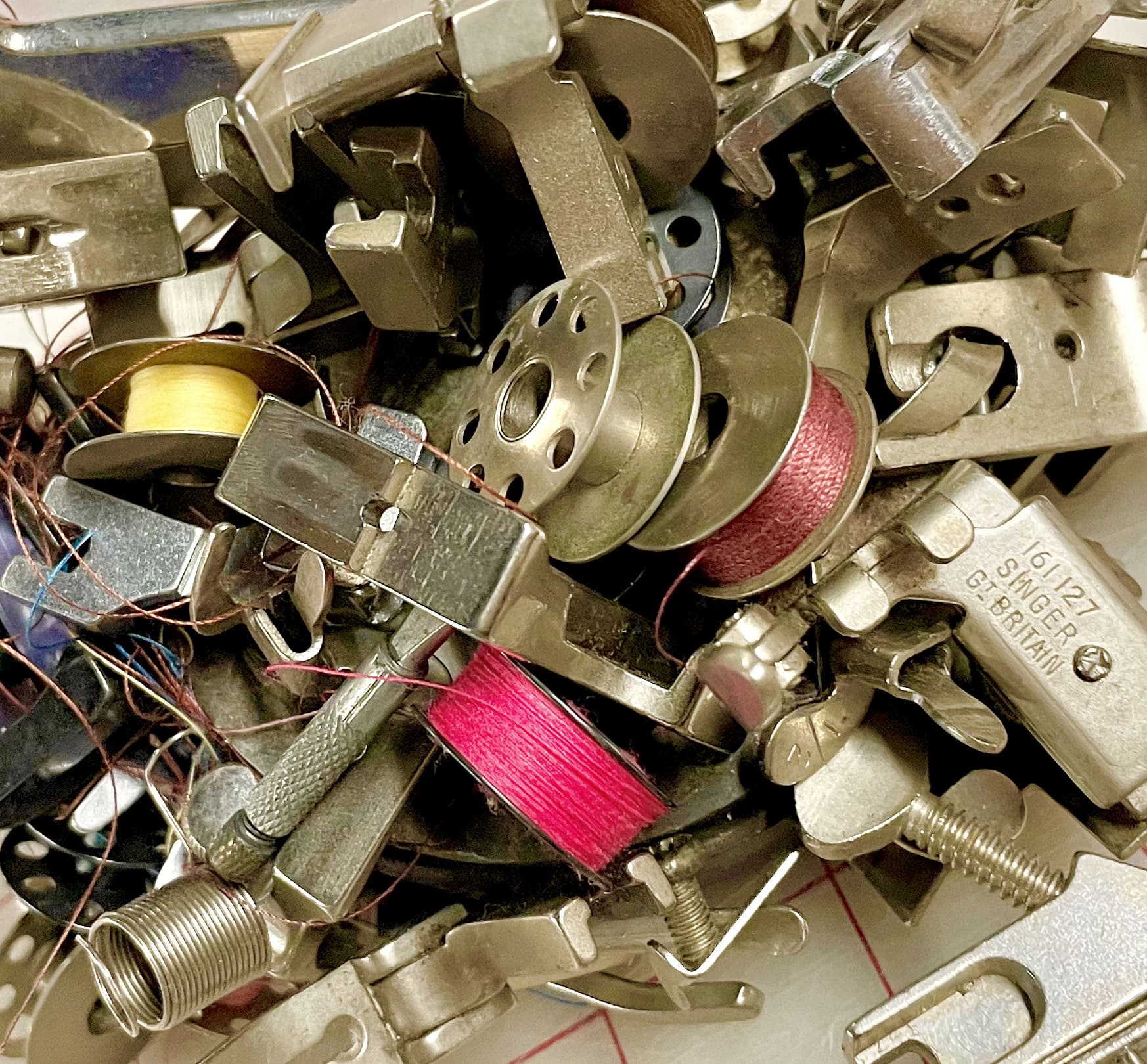

2. Maintain Equipment Regularly

Well-maintained equipment is essential for accurate and efficient sewing. Whether you’re using industrial sewing machines or more basic models, regular maintenance is key to avoiding errors. At Sewing Patterns & More, we recommend frequent cleaning and servicing of machines to keep them in top working condition. Regular oiling, needle changes, and tension adjustments can prevent issues like skipped stitches or fabric damage.

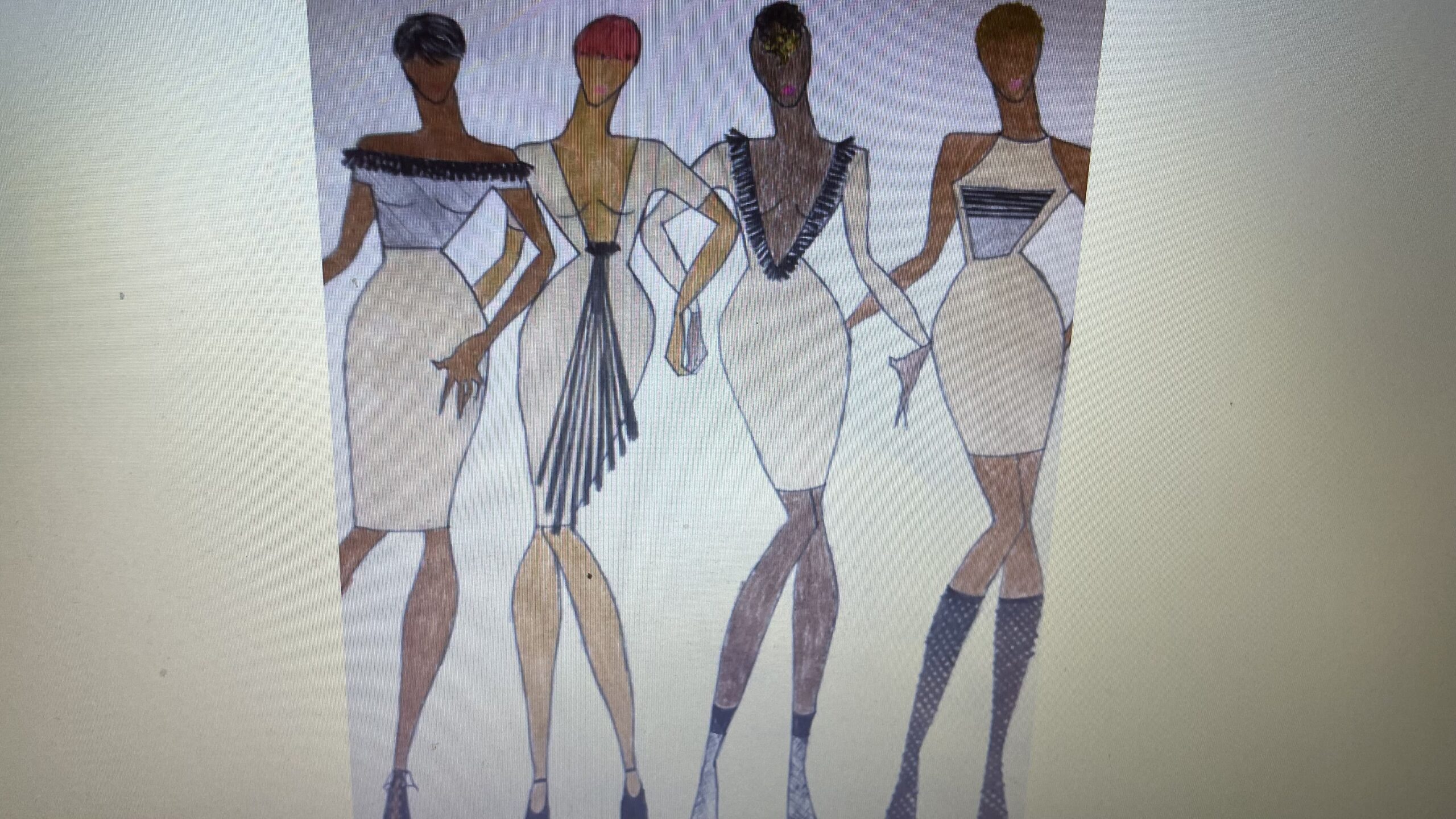

3. Train Your Team

At Sewing Patterns & More, we believe in the power of skilled workers. Ensuring that your team is trained in the best practices for sewing, cutting, and finishing is a critical step toward quality control. Invest time in training programs that cover both basic and advanced sewing techniques. This not only improves the quality of your products but also enhances the speed and efficiency of production. Empower your workers to check their own work for mistakes before moving on to the next step in the process.

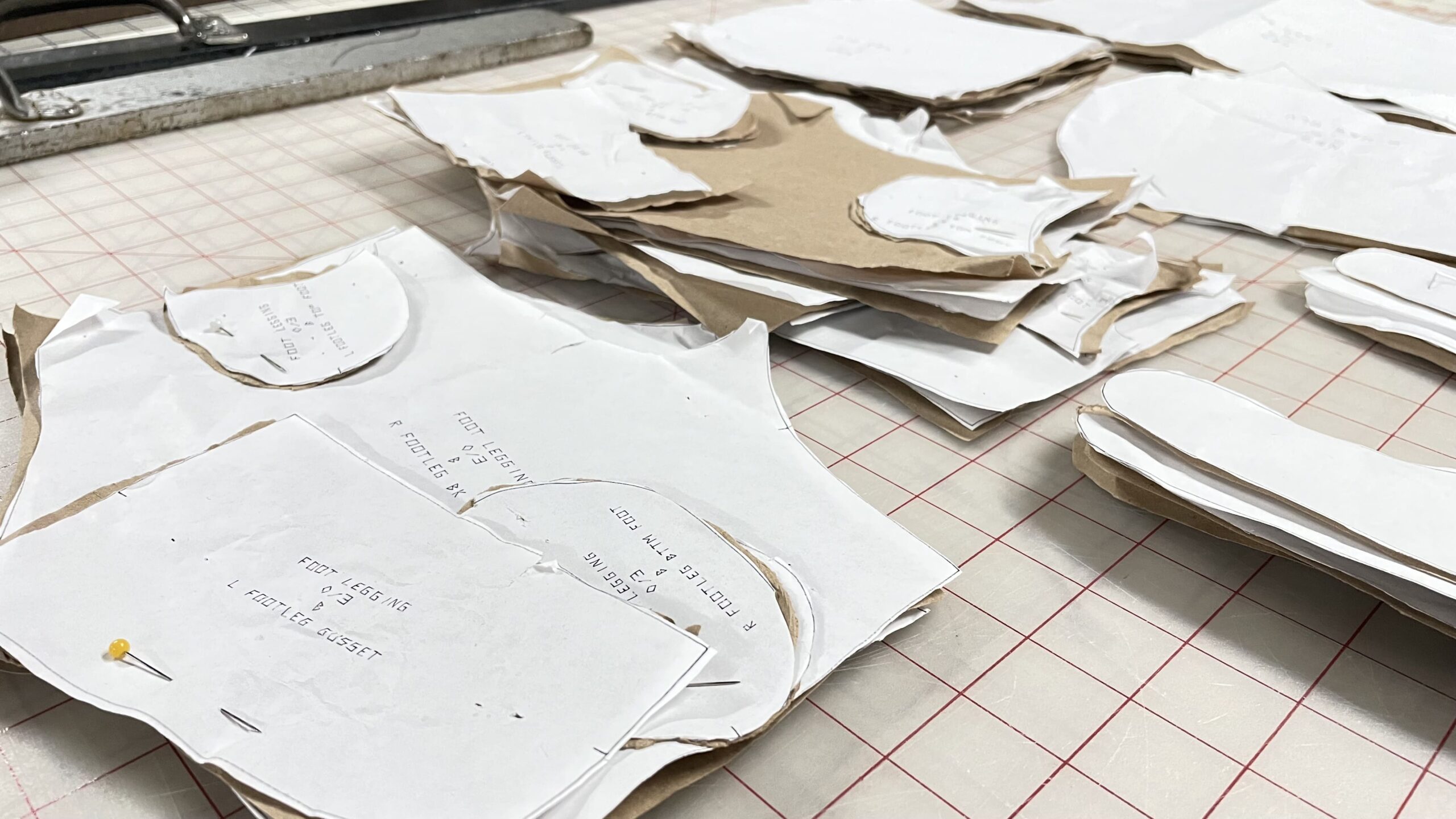

4. Implement Regular Inspections

Implementing a regular inspection system can significantly reduce errors. At Sewing Patterns & More, we advocate for multiple stages of quality control during the production process. For example, after cutting, pieces should be inspected to ensure accuracy. During sewing, random checks should be conducted to verify the consistency of stitches, seams, and alignment. And before packaging, a final inspection ensures that the product meets all quality standards.

5. Develop a Standard Operating Procedure (SOP)

Consistency is key to maintaining high-quality standards, which is why Sewing Patterns & More recommends developing a Standard Operating Procedure (SOP) for your sewing process. This ensures that every worker follows the same guidelines, from fabric cutting to the final stitches. Your SOP should include clear instructions on how to handle specific tasks, along with acceptable tolerances for errors (e.g., stitch length deviations or seam allowance accuracy). A well-documented SOP minimizes variability in production and enhances overall product quality.

6. Use Technology for Precision

Technology can be a valuable tool for improving quality control. At Sewing Patterns & More, we use computer-aided design (CAD) software and automated cutting machines to ensure precision in pattern making and fabric cutting. If you’re producing in larger quantities, consider investing in machinery or software that improves accuracy and efficiency, reducing the margin for error. In addition, tools like fabric inspection machines can help catch defects before sewing begins.

7. Customer Feedback Loop

At Sewing Patterns & More, we value customer feedback as an essential part of our quality control process. Listening to your customers can help you identify recurring issues, such as fit problems or durability concerns, which may not be immediately visible during production. Create an easy way for your customers to provide feedback, and make sure to address any quality concerns quickly. This not only helps you improve but also strengthens your relationship with your clients.

8. Continuous Improvement

Quality control is not a one-time task; it’s a continuous process. At Sewing Patterns & More, we are always looking for ways to improve our quality control systems. Regularly review your processes, identify areas for improvement, and be willing to adapt new techniques or technology to maintain your standards. Encouraging a culture of continuous improvement ensures that your products remain competitive and your reputation stays strong.

Conclusion

Quality control in sewing is essential for producing products that meet customer expectations and stand the test of time. By following these tips and strategies, you can ensure that your sewing projects consistently achieve the highest quality standards. At Sewing Patterns & More, we are committed to helping businesses and individuals succeed by providing resources, patterns, and advice tailored to your sewing needs.

Ready to Elevate Your Sewing Quality?

If you’re ready to take your sewing projects to the next level, Sewing Patterns & More can help! Submit your proposals using using this form, and let’s collaborate to ensure your designs meet the highest quality standards.